KEEPING THE SPARK ALIVE: THE IMPORTANCE OF SPARK PLUG MAINTENANCE

You get in your car on a winter’s morning and turn the key. The starter receives a boost from the frozen battery and struggles to turn the engine’s crankshaft. Another turn of the key and it makes no difference... Your neighbor jokingly asks “if the spark has gone” and, to be honest, he’s probably right!

WHAT THE SPARK PLUGS WILL TELL YOU

Cold weather starting issues with petrol engines tend to be caused by poor battery condition and dampness, but the condition of the spark plugs can also contribute to the problem.

As service manuals detail when a car’s fluids should be changed, they also specify when the spark plugs should be replaced.

As a rule, the minimum service life of spark plugs is about 20,000km, but it is worth checking them before the onset of colder weather as an easy engine start in winter depends largely on their condition. As well as igniting the petrol/air mixture in the combustion chamber, the spark plug can also give an indication of an engine’s condition and problems associated with its operation.

If the skirt of the insulator is burnt, and the center electrode is partially melted, then this can be caused by a whole host of problems spanning the use of the wrong thermal grade of spark plug to a faulty valvetrain or bad fuel.

Noticed soot on the electrodes? This problem is most likely related to an air/fuel ratio, while traces of oil on the electrodes means the piston rings, valve seals and PCV (Positive Crankcase Ventilation) valve are worth checking and, in the case of a supercharged engine, the condition of the turbine. You could go on and on – spark plugs really can provide a lot of important information. Of course, in all these cases, the spark plugs need to be replaced, even if they have not reached their specified service life.

You can use the Champion Spark Plugs Trouble Tracer Chart to determine the root cause of any spark plug issue.

MORE SPARK PLUGS FOR A GREATER CHOICE

Today's automotive aftermarket is overflowing with parts, making it difficult to choose the right product. Here are some important points about the features of Champion spark plugs:

- Champion spark plugs are preferred by many vehicle manufacturers as original equipment.

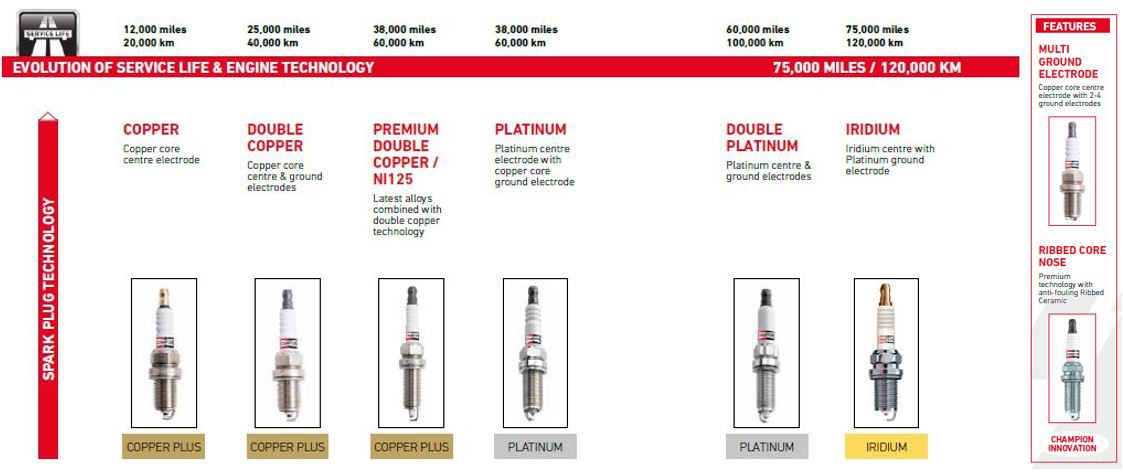

- Champion spark plugs are produced based on OE technologies. The company's catalogue contains a huge number of items representing a variety of technologies: from copper and platinum up to iridium.

- The most advanced spark plug offered by Champion is that which uses Iridium technology for modern turbo engines, which allows a spark plug to last longer. Iridium is one of the strongest metals used in spark plugs. Moreover, Iridium considerably increases the service-life of the plug. Champion undertook ground-breaking work in developing this impressive spark plug technology. Highlights of this OE-like spark plug include:

o Exclusive Heat-Active™ alloy reaches operating temperature quickly and maintains stable operation.

o The Multi-Layer Rivet Technology is the welding process used by Champion that optimizes the service-life of the spark plug.

o Champion’s SureFire™ Ceramic technology reaches a higher density, lower porosity, and temperatures under varying engine loads.

o Nickel 125 alloy ground electrode in combination with proprietary Iridium Fine-Wire center electrode produces the sharpest spark focus, ensuring unprecedented erosion resistance and longer product lifetime.

o A built-in FISS (Fired In Suppressor Seal) suppression resistor eliminates possible radio frequency interference (RFI), which guarantees perfect ignition and trouble-free operation of all electronic on-board systems.

- While it is recommended to change copper spark plugs after 20,000 km, iridium spark plugs can last up to 120,000 km. Of course, the Champion range also includes references adapted to specific engines. This is due to the trend towards compact engines with small displacement. For example, the V8 TFSI engines for Audi A6, A7 and A8 models have very deep spark plug wells. Therefore, in addition to a special plug design a special cupped connector is used. Champion also offers a versatile EON Titan compact range of spark plugs, including nine reference numbers for atmospheric engines and the same number for turbocharged engines.

SPARK PLUGS TECHNOLOGY

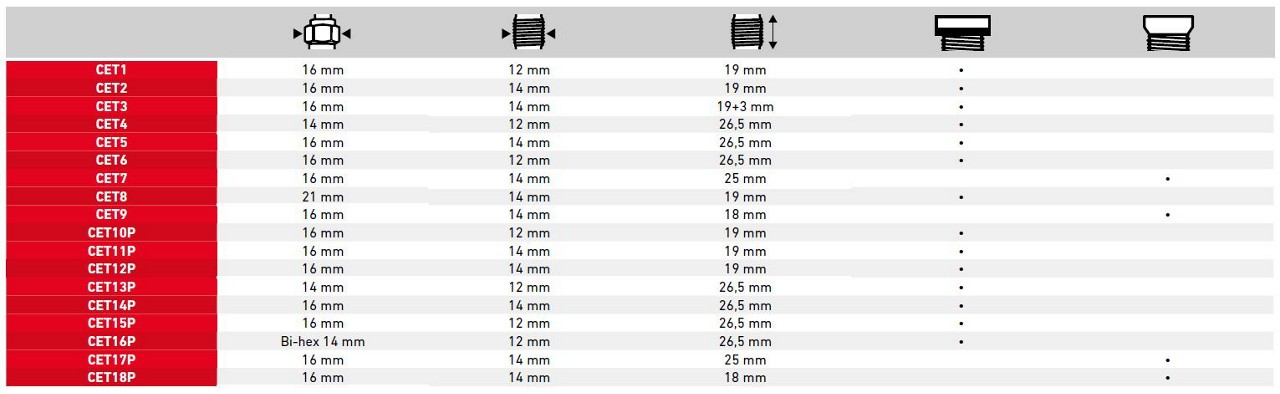

INSTALLATION INSTRUCTIONS EON TITAN SPARK PLUGS

WHAT IS IMPORTANT TO KNOW ABOUT SPARK PLUGS

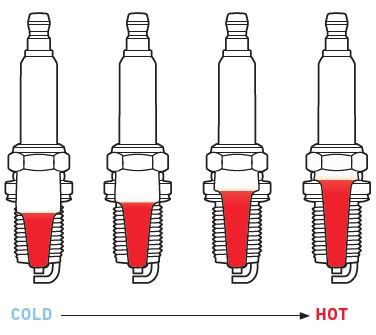

An important parameter for a spark plug is a heat grade, a value that determines the ability of the spark plug to dissipate heat from the combustion chamber. The lower the heat grade number of the spark plug, the higher its heat dissipation capability. It's no coincidence that so-called "cold" spark plugs, i.e., plugs with a low heat grade, are used in racing engines. As a rule, low-number heat grade plugs have a short insulator skirt, which absorbs less heat and allows for good heat dissipation thanks to the longer contact area between the insulator and metal housing. So-called “hot” spark plugs have a longer insulator skirt and shorter contact area between the insulator and metal housing with less capability to dissipate heat from the combustion chamber. It helps keep the electrodes at a higher operating temperature and reduce wet deposits from forming. This type of spark plug is mainly used in less powerful engines. It's worth noting that the Champion compact range of spark plugs is characterized by a wide range of heat grade numbers. For example, a particular application in the EON Titan range of "cold" spark plugs can have a heat grade range of 4-6 or even 2-6.

HEAT GRADE RANGE

INSTALLATION TIPS & TRICKS

When it comes to fitting the spark plugs, there are several important points to consider.

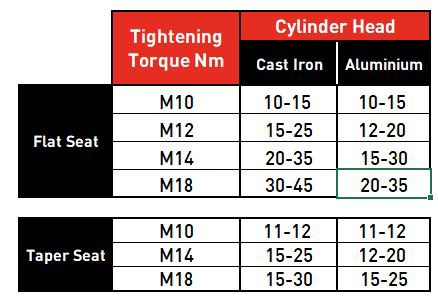

The spark plug socket in the engine block can have either a flat or conical seat. The spark plug housing is also shaped accordingly. The seat prevents the combustion chamber from leaking using a compression gasket or taper interface seat. Each spark plug has a specific seat type which is not interchangeable.

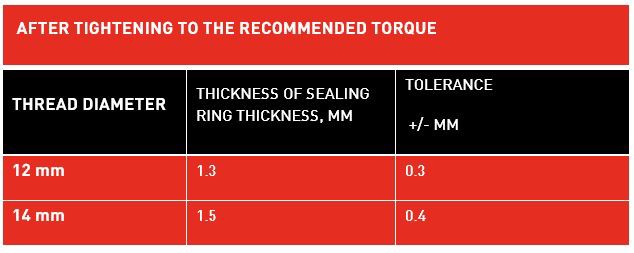

Spark plugs with a flat seat are used in engines designed for a gasket seal. Spark plugs with a tapered seat are used in engines designed for a tapered seal. When tightening the spark plug with the recommended torque value, the gasket seal experiences a plastic deformation and thus provides a seal. This should be done with a torque wrench - there is a reason why the recommended tightening torque is indicated in our catalogue and on the Champion spark plug packages.

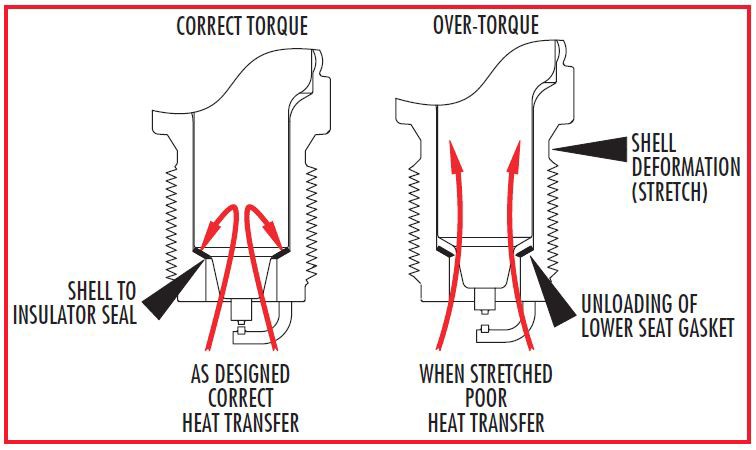

Overtightening of the spark plug often causes combustion gases to leak through the internal part of the spark plug, breakage, or separation of the insulator from the metal housing.

If the spark plug is not tightened sufficiently, there is a high probability of gas escaping from the combustion chamber through the loose connection. Overtightening can cause misfiring of the spark plug due to extension of the metal housing and with this increase in the gap between electrodes. Overtightening of the spark plug often causes combustion gases to leak through the internal part of the spark plug, breakage, or separation of the insulator from the metal housing. When re-installing a previously overtightened spark plug, it may cause a leak due to the residual thickness of the gasket seal washer being insufficient to ensure a tight seal. When removing the spark plug, the residual thickness of the seal washer can determine whether excessive tightening force has been applied.

Unfortunately, even at a professional garage, installers do not always use a torque wrench when installing spark plugs. There is no need to lubricate the thread of the spark plug when installing, as all Champion spark plugs are anodized. Also applying lubricant to the thread reduces the friction coefficient, and the spark plug may be overtightened even if it was installed with the recommended torque value. The recommended torque value (in Nm) for Champion spark plugs is always indicated in our catalogue, and on the spark plug’s individual box together with the inter-electrodes gap specification in mm.

Influence of the tightening torque value on the spark plug performance:

Recommended tightening torque values:

The second important point when fitting the spark plug is to check the electrode gap. It is pre-set by the spark plug manufacturer, but it is worth checking this parameter as the incorrect gap can lead to ignition misfire. However, if it becomes necessary to adjust the gap, it must be done very carefully as a piece of damaged side electrode may end up in the combustion chamber. Never drop the spark plug to the bottom of a long spark plug well in the cylinder head. This could change the electrode gap and cause misfiring. Use a piece of hose or an old modular ignition coil for installing and tightening spark plugs by hand.

And one more diagnostic-related tip. Sometimes you can see a black stripe running along the insulator surface on an already working spark plug. This is a puncture mark. Most likely, the problem is caused by the high voltage cap, which has become "swollen" and cracked from old age. It can be easily determined if you press the high voltage cap with two fingers. If cracks are present, they will be clearly visible. The cap should be replaced and to minimize the risk of this problem recurring, apply a special dielectric grease to the spark plug insulator where the cap is in contact.

If the vehicle runs on Liquefied Petroleum Gas (LPG), special attention must be paid to the correct choice of spark plug. The combustion temperature in LPG operation is approx. 200°C higher than for gasoline operation. LPG fuels are also offered with different mixture ratios, depending on the season of the year. The air requirement changes accordingly: winter gas requires less air for combustion. Consequently, the oxygen value increases, the operation of the engine is too lean, and the exhaust gas temperatures will increase. The result: the engine overheats and burns the spark plug electrodes and the outlet valves.

Champion therefore recommends the use of spark plugs with a thermal rating that is one grade lower: For example, if a spark plug with a thermal rating of 7 is installed, it must be exchanged for a spark plug with a thermal rating of 6. Set the electrode gap to 0.7 mm, if the design of the spark plug allows this. Experience has shown that this ensures the best spark for this use. It is preferable to use spark plugs with metals like platinum and iridium since erosion of electrodes is higher for LPG. The average running period of the spark plug on rebuilt engines is approximately 20,000 – 30,000 km.

CONCLUSION

The spark plug is one of the petrol engine’s smallest components, but it’s a part that also has one of the biggest tasks to perform. Not only is it vitally important in starting the engine and literally keeping it firing on all cylinders, the spark plug, via its appearance, also provides an insight into the engine’s condition in a matter of seconds. Neglect the spark plug and it has the potential to destroy an owner’s enjoyment of their vehicle, imparing both starting and running. With the spark plug having such an important role, it’s also imperative to choose a quality replacement. Only opting for a trusted, well-proven brand like Champion guarantees that a car will run and perform as the manufacturer intended.

Want to know more?

Interested in knowing more about maintenance and tips on servicing it? Check our technical data sheets page and download the relevant files.

Enjoy access to free online maintenance courses by registering for our e-learning platform or visit the Garage Gurus YouTube channel.

This article is for informational purposes only. We are not liable for any damages resulting from your reliance on this content. This check list only provides general advice and cannot be referred to as a completed and final guide to each driver's responsibility to ensure that her/his vehicle is in a proper working condition and ready for use on the road.

English

English