THE ESSENTIAL GUIDE TO BRAKE GREASE: BEST PRACTICES AND APPLICATIONS

The correct type and application of brake grease can help reduce vibration, squeal and other noises, the pads dragging against the brake disc and malfunction due to uneven contact.

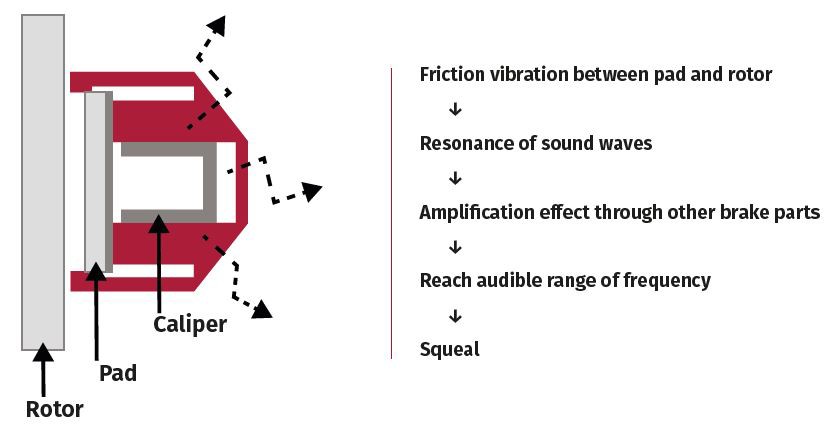

NOISE GENERATION

When the brake pad presses against the disc surface when the car moves, it generates vibration which is then transmitted to other brake system components and the chassis. It’s possible that the frequency of this vibration coincides with the natural frequency of any of these components. Thus, we would witness the phenomenon of resonance. If any of the components vibrates at the audible frequencies, we can hear a noise during braking.

Therefore, they can vibrate during braking and at the same time make a sound: a disc, a caliper bracket, a steering knuckle, a dust shield of a brake disc, a shock absorber strut, a spring and even a suspension beam may be the source of vibrations in audible frequency range, generating noise.

One of the measures to combat brake noise is the use of special brake grease that, where applicable, is added in a small amount to the back of the pad and on its guides/abutments, and caliper guideline. The type of grease used should be metal free, high-temperature resistant and be rubber compatible.

NEVER use copper-based grease for brake system parts since it could cause electrochemical corrosion and may also lead to sticking at high temperatures.

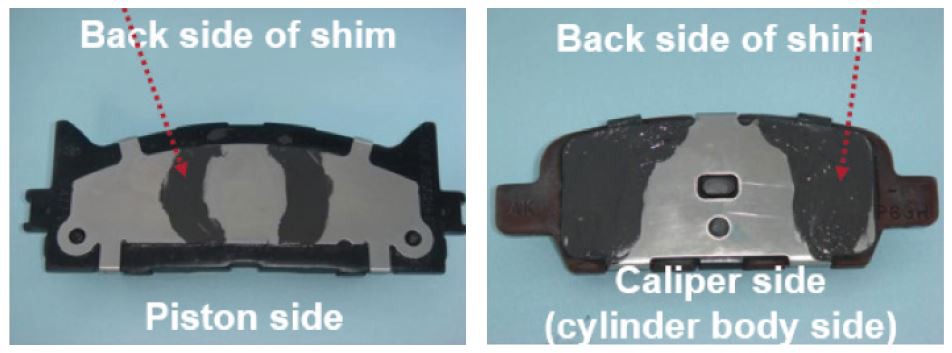

Never apply grease on the back plate of the pads with an adhesive foil. The foil secures the brake pad to the caliper and avoids movement, and therefore doesn’t require grease application.

CORRECT INSTALLATION STEPS

- Clean and check the caliper

After disassembly, check and clean the mounting surfaces on the brake calipers to ensure maximum sliding effort of 3 - 4 kg.

- Brake grease application

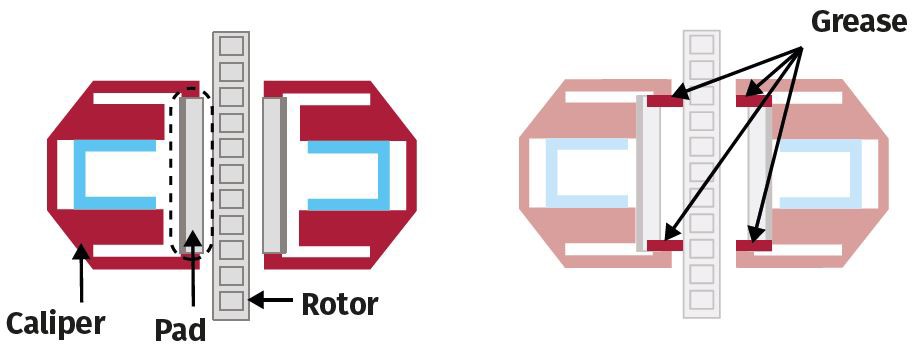

A small amount of a special temperature-resistant brake grease can be applied to the following components:

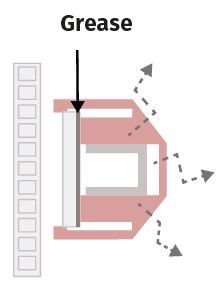

By applying the grease to the back of the brake pad, you can reduce the sound wave that causes resonance. The damping effect from the lubrication cuts off the transmission of friction vibration from the pad to the piston, preventing brake noise.

PADS DRAGGING AGAINST BRAKE DISC

When the brakes aren't applied but the pad and rotor come into a contact, it is called 'dragging'. If dragging occurs, fuel consumption can increase by up to 4%. It can also result in a loss of steering control, an abnormal rise in brake temperature and the engine stalling. The main reasons for dragging are corrosion and poor lubrication at abutments. Special brake grease helps the pad work properly and improves pad behavior by preventing locking and malfunction, effectively working to stop dragging from happening. Under normal conditions, clearance between the rotor and pad is less than 0.1 mm. For controlling such a small clearance, it's vital to have the correct, special grease.

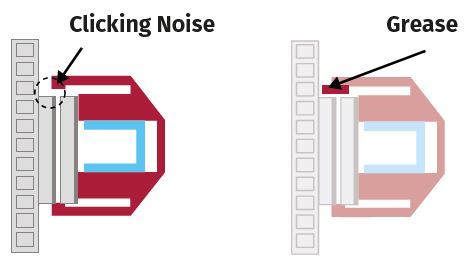

CLICKING NOISE

Applying brake grease to the pad guides/abutments and caliper guidelines will help to reduce any clicking noise, the grease acting like a damper to prevent any looseness between the pad and the support.

WHEN TO USE BRAKE GREASE

Brake grease is recommended when:

- Brake pads are replaced;

- The brake system is overhauled;

- Long distance driving is undertaken;

- Experiencing stop-and-go driving in traffic jams;

- A car is not likely to have regular use;

- Frequently driving in mountain or seaside areas;

- Driving in the cold season

- You hear squeaking or abnormal brake noises;

- You feel vibrations through the steering wheel and pedal when you apply the brakes;

- If you feel the fuel efficiency is decreasing

Ferodo offers a special type of brake grease. Ferodo Brake Grease (FBG001) is a copper- free mounting paste based on high viscosity silicon oil, containing also pure natural graphite. It has a perfectly balanced silicone-graphite composition, which will facilitate the movement of the pads, and serve as a useful ballast, slightly increasing the mass of the pads and, thus, changing the frequency of natural vibrations. It also acts like an additional damper. This composition is widely used in motorsport, where high friction coefficients of pads often trigger brake noise.

High quality brake grease should be certified using standard tests and meet the following requirements:

Durability:

To evaluate the grease durability, evaporation loss under 200°C for 500hrs is one of the main conditions, certified using standard tests. This is the equivalent of 30,000 Km driving. Low evaporation loss is a main indication of a high-performance grease.

High damping effect:

Resonance between a pad and a caliper is reduced by the damping effect of grease, therefore friction vibration between a pad and rotor will not resonate within the caliper, hence preventing noise amplification. Some greases will exhibit some damping capability, at certain levels. A higher Specific Damping Capacity (SDC) percentage leads to better damping performance.

Rubber compatibility:

Mineral oil-based greases not only have short-term durability, but can damage rubber parts, which can lead to accidents. Therefore, in recent years, mineral greases are no longer being used for disc brake applications. Rubber compatibility is represented by a compatibility test during which the boot ring is immersed for several hours in the sample grease for observing its effect on the rubber condition at room temperature.

Ferodo high quality grease should not shrink and swell. Ferodo high quality brake grease is certified using the above standard tests and has long durability, high damping, and rubber compatibility. Brake grease can increase the efficiency of the braking system, enhance fuel efficiency and eliminate brake noise/squeal.

Want to know more?

Interested in knowing more about braking tips? Check our technical data sheets page and download files related.

Check out our online braking courses by registering in our e-learning platform for free or visit the Garage Gurus YouTube channel.

The content contained in this article is for informational purposes only and should not be used in lieu of seeking professional advice from a certified technician or mechanic. We encourage you to consult with a certified technician or mechanic if you have specific questions or concerns relating to any of the topics covered herein. Under no circumstances will we be liable for any loss or damage caused by your reliance on any content.

English

English